|

Ø

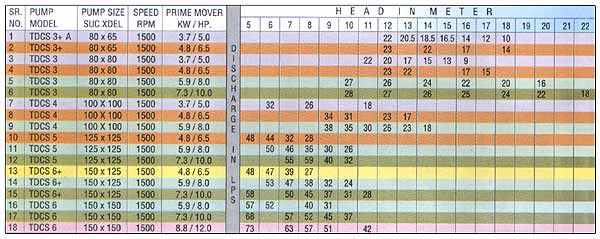

Pumps >> Type TSD :::

|

•

The pump is made for coupling with electric motor, diesel

engine with the help of belt.

•

The direction of rotation is clockwise viewing from pulley

end.

•

The pump is solid in construction, vibration proof and easy

in handling.

•

The pump is supported with robust ball bearings.

•

Casing is made of high quality close grained cast iron with

well-designed volute way ensuring smooth flow with gradual

changes in velocity and is hydraulically tested before final

assembly.

•

Impeller is of single end suction, shrouded type made of

special Grey Iron with high finish and impeller is dynamically

as well as statically balanced.

•

Shaft is made from high quality steel and accurately ground

finished within the manufacturing tolerances, and the size

of the shaft is designed for transmitting maximum power

without vibrations.

•

Supporting frame is robustly constructed to carry shaft,

single as well as double bearings and brass bush.

•

Stuffing box is of liberal depth for accommodating sufficient

gland packing. Easy access to stuffing box is an outstanding

feature of Supporting Frame, facilitating convenient replacement

of Gland packing.

|

Application

- Water

supply from fountains, lakes, rivers; water transport through

the pipelines over long distances

-

Irrigation of the Agricultural Farms.

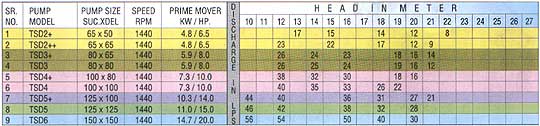

Technical Data

Suction

/ Discharge Diameter...... upto 6 inch

Capacity....................................... upto 56

lps

Pumping head ............................. upto 22

meter

Suction head ............................... Max.6

meter

|

Prime

Mover Capacity .................. upto 5 to 20

hp

Revolution Per Minute ................. 1440

rpm

Max. Working Pressure ................ 3.5

Bar |

Operating

Range

Important

•

To get best performance use best frictionless Pipes & Foot

Valves.

•

The suction pipe should be as short as possible.

•

The weight of suction & delivery pipes should not be applied

to pumps.

•

The pump should be carefully aligned during its installation.

•

The pump should not be operated dry.

•

The gland should Not Permit more then 30 drops Per Minute, If it

does please tighten it.

Note

::

The Performance data are at rated R.P.M. and only indicative, in

view of continuous development the information/description/specification

illustration are subject to change without notice.

|

Ø

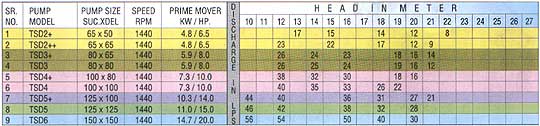

Pumps >> Type TDCV:::

•

The pump is made for coupling with electric motor and diesel

engine.

•

The direction of rotation is anti-clockwise viewing from

pulley end.

•

The pump is solid in construction, vibration proof and easy

in handling.

•

The pump is supported with robust ball bearings.

•

Casing is made of high quality close grained cast iron with

well-designed volute way ensuring smooth flow with gradual

changes in velocity and is hydraulically tested before final

assembly.

•

Impeller is of single end suction, shrouded type made of

special Grey Iron with high finish and impeller is dynamically

as well as statically balanced.

•

Shaft is made from high quality steel and accurately ground

finished within the manufacturing tolerances, and the size

of the shaft is designed for transmitting maximum power

without vibrations.

•

Supporting frame is robustly constructed to carry shaft,

single as well as double bearings and brass bush.

•

Stuffing box is of liberal depth for accommodating sufficient

gland packing. Easy access to stuffing box is an outstanding

feature of Supporting Frame, facilitating convenient replacement

of Gland packing.

|

Application

- Water

supply from fountains, lakes, rivers; water transport through

the pipelines over long distances

-

Irrigation of the Agricultural Farms.

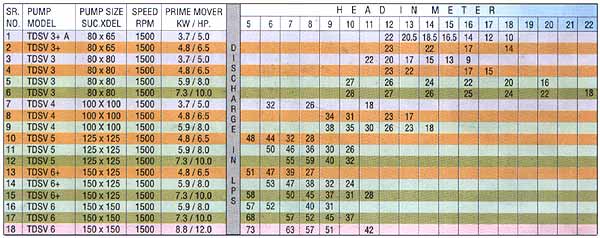

Technical Data

Suction

/ Discharge Diameter...... upto 4 inch

Capacity....................................... upto 44

Lps

Pumping head ............................. upto 25

meter

Suction head ............................... Max.6

meter

|

Prime

Mover Capacity .................. upto 5 to 10

hp

Revolution Per Minute ................. 1500

rpm

Max. Working Pressure ................ 3.5

Bar |

Operating

Range

Important

•

To get best performance use best frictionless Pipes & Foot

Valves.

•

The suction pipe should be as short as possible.

•

The weight of suction & delivery pipes should not be applied

to pumps.

•

The pump should be carefully aligned during its installation.

•

The pump should not be operated dry.

•

The gland should Not Permit more then 30 drops Per Minute, If it

does please tighten it.

Note

::

The Performance data are at rated R.P.M. and only indicative, in

view of continuous development the information/description/specification

illustration are subject to change without notice.

|

Ø

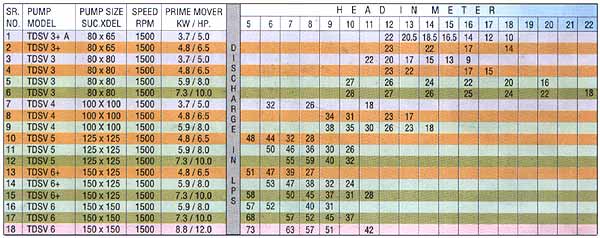

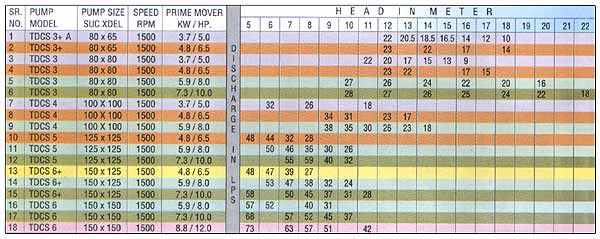

Pumps >> Type TDCS :::

•

The

pump is made for coupling with electric motor and diesel

engine.

•

The direction of rotation is anti-clockwise viewing from

pulley end.

•

The pump is solid in construction, vibration proof and easy

in handling.

•

The pump is supported with robust ball bearings.

•

Casing is made of high quality close grained cast iron with

well-designed volute way ensuring smooth flow with gradual

changes in velocity and is hydraulically tested before final

assembly.

•

Impeller is of single end suction, shrouded type made of

special Grey Iron with high finish and impeller is dynamically

as well as statically balanced.

•

Shaft is made from high quality steel and accurately ground

finished within the manufacturing tolerances, and the size

of the shaft is designed for transmitting maximum power

without vibrations.

•

Supporting frame is robustly constructed to carry shaft,

single as well as double bearings and brass bush.

•

Stuffing box is of liberal depth for accommodating sufficient

gland packing. Easy access to stuffing box is an outstanding

feature of Supporting Frame, facilitating convenient replacement

of Gland packing.

|

Application

- Water

supply from fountains, lakes, rivers; water transport through

the pipelines over long distances

-

Irrigation of the Agricultural Farms.

Technical Data

Suction

/ Discharge Diameter...... upto 6 inch

Capacity....................................... upto 73

Lps

Pumping head ............................. upto 25

meter

Suction head ............................... Max.6

meter

|

Prime

Mover Capacity .................. upto 5 to 12

hp

Revolution Per Minute ................. 1500

rpm

Max. Working Pressure ................ 3.5

Bar |

Operating

Range

Important

•

To get best performance use best frictionless Pipes & Foot

Valves.

•

The suction pipe should be as short as possible.

•

The weight of suction & delivery pipes should not be applied

to pumps.

•

The pump should be carefully aligned during its installation.

•

The pump should not be operated dry.

•

The gland should Not Permit more then 30 drops Per Minute, If it

does please tighten it.

Note

::

The Performance data are at rated R.P.M. and only indicative, in

view of continuous development the information/description/specification

illustration are subject to change without notice.

Back

|

|

|

|